Product Design FMEA and Fault Tree Analysis: Addressing Issues Preventively

The more novel and the more complex a product design is, the higher the risks of running into technical issues. […]

How To Write Good Work Instructions for Production Operators & Inspectors [9 Tips]

Documenting the standard way of performing production and inspection work is part of the ‘best practices’ all good manufacturers follow. […]

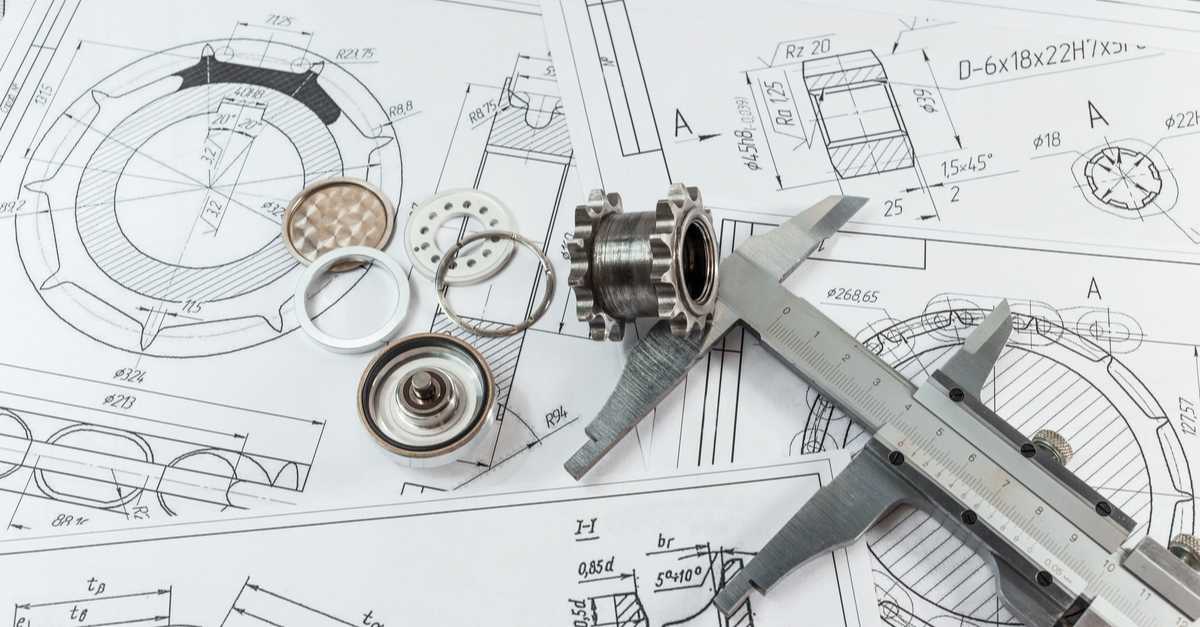

6 Ways 2D Drawings Help Communication Through Development & Production

Have you been working on the design of a new product? Maybe you are in the prototyping phase, you are […]

How To Create A Valid Manufacturing Contract In China To Protect Your IP

China is the perfect location for start-up companies and SMEs from all over the world to bring innovative products to […]

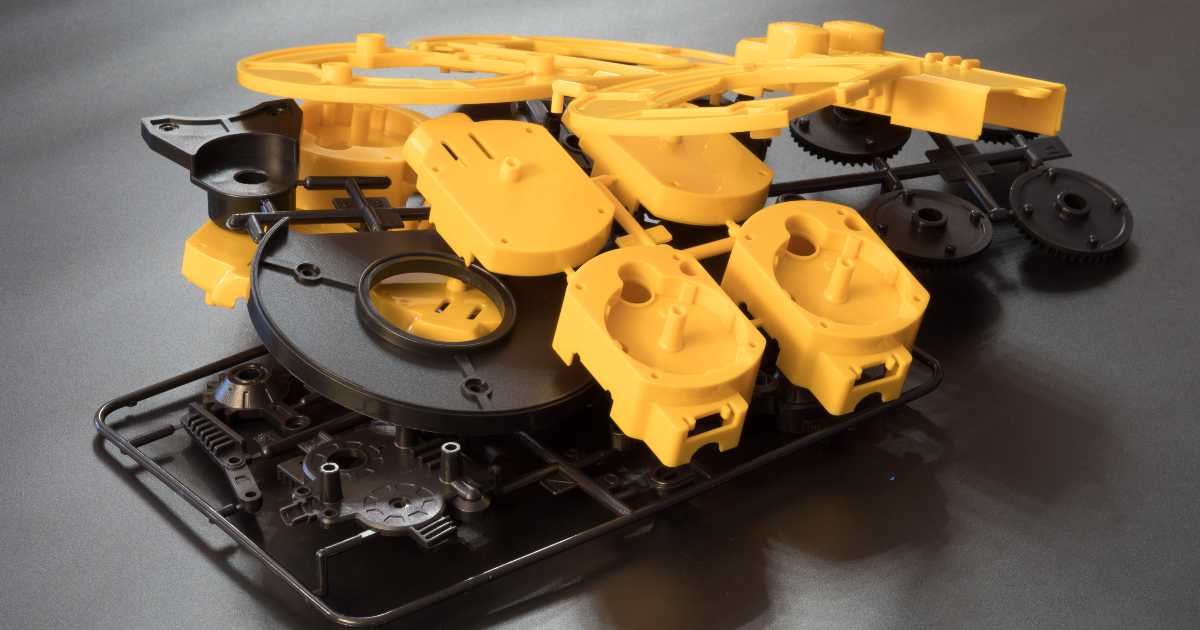

Common DFM Improvements On Plastic Injection Molded Parts

How do you ensure your design is mature, and you are ready to order the fabrication of the mold for […]

Why Keeping Component Suppliers In The Dark Is Good IP Protection For Manufacturers

There are two complementary approaches to improve IP protection for manufacturers and reduce the risks of your IP being infringed […]

What Common Improvements Can DFM Make To Die Cast Parts?

Die-cast parts can be improved by utilizing DFM principles before making tooling. This post guides you through DFM best practices, common defects, and more.

How To Manage the Bill of Materials, from Initial Design to Mass Production

When developing and making a new product, the Bill of Materials (BOM) is one of the most important documents – […]

5 Tips To Select a Great Contract Manufacturer in China or Vietnam

If you develop your own products, and if you intend to make many thousands of them in China or Vietnam, […]

How To Qualify Component Suppliers At The Design & Prototyping Stage

At Agilian, we mostly work on totally new products. It is a rare project that doesn’t force us to use […]

Why A Feasibility Study With Suppliers Saves Time & Prevents Issues

One of the root causes of many quality issues is poor communication, and it is particularly true in China. When […]

Why spending time in planning, before starting prototype work, can save a lot of time

Many clients come to us with a product design and expect that we start building a prototype immediately, but in […]

What Makes a Good Quality Standard?

Aligning everyone’s understanding of “what is acceptable” and “what is not acceptable” into a quality standard is very important. And […]

Why A Pilot Run On A New Product, Before Mass Production, Is Very Helpful

Prototypes are useful in confirming the details of the product to manufacture. However, they are usually not made with the […]