Get experienced help from our engineers to help with engineering work (mechanical, electronic, or firmware) where needed, create your prototype, and comment on whether your design is fit for mass production. Most startups, as well as many midsize companies, lack product development experience and missteps in the R&D phase have long-lasting consequences. This is where we step in to support your project and help you bring it to the next level.

Why Agilian?

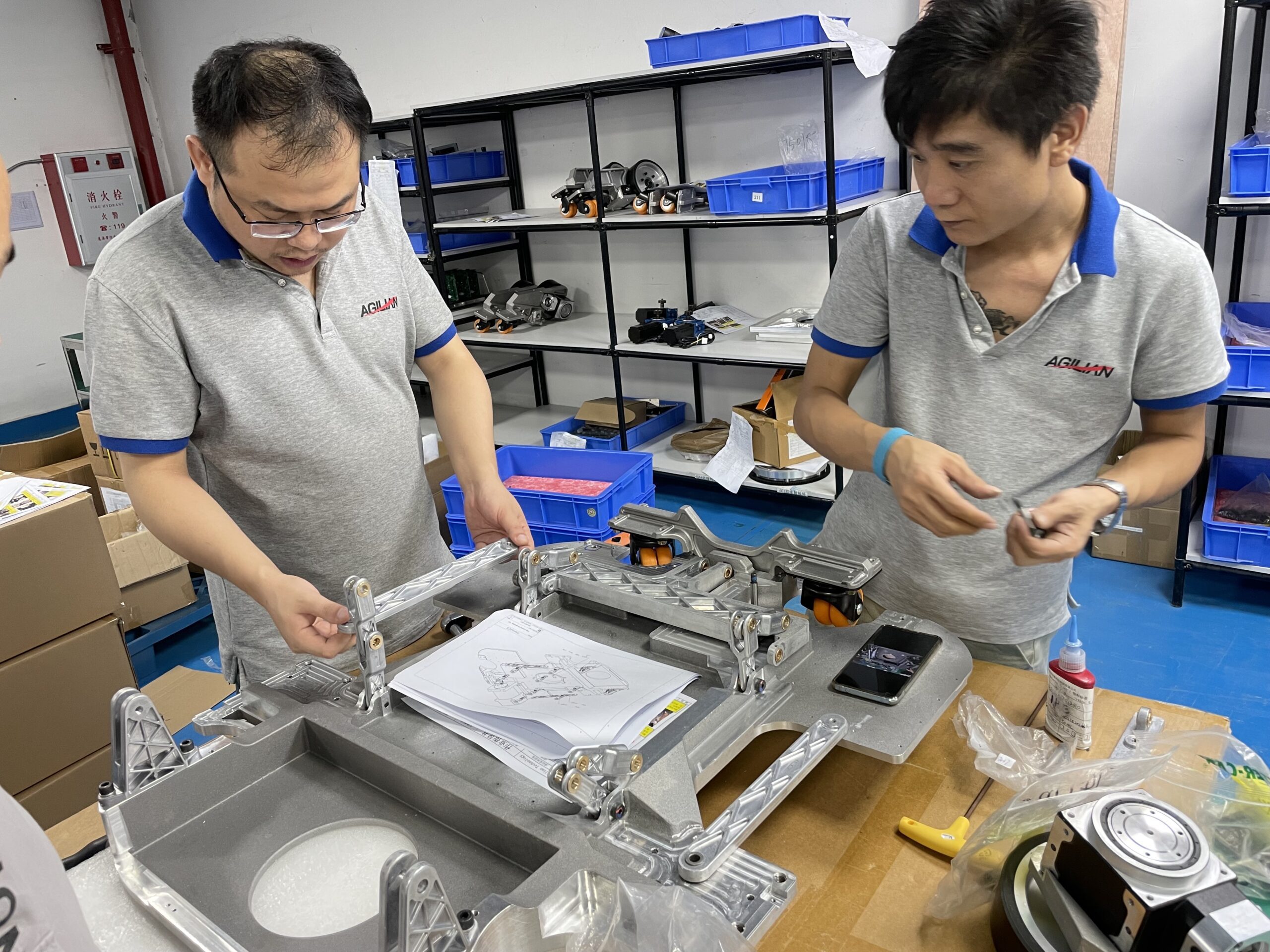

We don’t just make parts (and we are familiar with many fabrication and surface treatment processes). We build fully functional products and we have a lab to test them, can write firmware, can do validation runs & testing of the entire product, and more, all under one roof.

We focus on the following during a prototyping project to ensure you’re on the way to successful manufacturing:

Design reviews

Changes at this stage are much faster and less expensive than down the line.

Research & development

Our team of mechanical, electrical, and electronic engineers in our R&D center are focused on moving your products from design to a prototype that is manufacturable in China.

Rapid prototyping

You want a first prototype, and then iterations, fast. We can do the job on-site for you.

Tooling development

Tools, jigs, or fixtures might be needed for manufacturing or testing. You get the help you need to develop them from our experienced team.

Ease of getting standard and custom components

We are in the middle of the World’s largest pool of component suppliers (of all sizes, quality, and service levels…) which makes it easy to obtain your components.

Certifications

We have broad experience to handle certifications of your product for your market(s).

Pilot runs

These are quite helpful for confirming that a new or complex product is ready for production at our facility.

Ease of access to specialized resources & processes

After 15+ years of export manufacturing, we have formed a deep network, from reliability labs to niche coating workshops.

The New Product Introduction process

For each project, we set a plan (with your agreement) for the process engineering, reliability testing, etc. needed to cut production risks.

Confidentiality

Which importer is not concerned about data confidentiality? That’s one of the reasons they opt to work with us. We keep your supply chain & product IP safe.

You need a “just do it” service.

You already have the drawings, schematics, etc. You need the parts to be made and shipped to you, without much critical thinking. That’s often the right approach for early ‘proof of concept’ prototypes, or for very simple products.

You need a review of your design and suggestions, not just making components.

You want to develop a product that is relatively easy to manufacture, with low risk of quality & reliability issues. Design reviews help prevent such issues when it is still easy.

You need a review, you also need help setting up a testing plan.

We always suggest that our customers set a testing plan (and we can work on defining it) and use that plan to check & approve the prototypes. The testing plan gets more mature as you get closer to production.

You need help with design work first, before any prototype can be made.

Maybe you don’t have the drawings and other technical documents necessary. Maybe you also need support on the supply chain side, to pick the right components from the start. We can help.

These are the most common ways we support our clients’ projects:

Structural & mechanical design

We review the industrial design (see the “Design for manufacturing” section below) and work on it into the details.

It involves creating the CAD drawings, suggesting improvements, discussing what is possible with component suppliers, and/or making simulations.

(Note: our clients usually have a design house work on the product’s aesthetics separately. We can put you in contact with design houses.)

Electronic design

For a complex new product, we may suggest to develop a ‘proof of concept’ based on Arduino. When it is time to get a full prototype that will be ready for production, we can design it from the ground up.

Based on what the product needs to

accomplish (specifications), we work on:

1. The block diagram

2. The schematic

3. The PCB layout

4. The prototypes

Firmware development

We have worked on projects that involved the following:

Languages: C (in Arduino), C (for PIC) Basic

Microcontrollers: American (PIC, AVR, STM8, STM32) Japanese (Renesas), Chinese (Fremont, Sinone, Neusoft, Cmsemicon, Chipsea), Taiwanese (Nuvoton, Holtek, Sonix, STC), and Arduino.

Chipsets: sensors (light, temperature, liquid, smoke, accelerometers, gyroscope), wifi, Bluetooth, USB controller, LCD, TFT related IC, power IC, charging IC.

Design for manufacturing

Do you want to get a final prototype that everybody loves, and later find out about enormous manufacturing challenges?

To avoid this, we plan for all the implications of the design on the manufacturability of components, on the ease and quality of assembly, on product reliability, etc.

We help adapt your concept to those constraints. We often suggest a better function-to-cost ratio (value engineering).

Mold design

Once the structural & mechanical design has been done into the details, designing tooling is often one of the next steps.

Our team has hands-on experience in plastic injection molding and die casting. We usually select & manage fabrication shops, review their mold design, and sign off on the molds and first trials.

Our engineers are often called in for troubleshooting during production, too

Technical support, with your suppliers

Does the design call for a complex manufacturing process for which your supplier has little experience?

Maybe we can help them pick the right materials, set up and control the process, etc.

Maybe a problem needs to be studied (root cause analysis, counter measures and verification, standardization).

We also often review an assembly line (layout & efficiency, testing stations…)

Our R&D team members come with a wide variety of engineering experiences.They have worked on the design & development of the following products.

Electronic products

- Electronic cigarette and its chargers

- Secured food box

- Home audio system

- Sweeper robot

- Waterproof audio system with Bluetooth

- Bone-conduction earphone

- Ruggedized mobile phone

- TV remote control

- Calculator

- Racing lamp mirror

- Industrial tablet computer

- Solar lamps

- Industrial control computer

- Interior LED lamps

- Intelligent Bluetooth terminal

- Hair dryer

- Shared power bank

- Hair straightener

- 3G network hardware

- Intelligent display and control equipment

Kitchen, home, and garden appliances

- Manual and electric wine corkscrews

- Humidifier

- Salt and pepper grinders

- Electric fan

- Vacuum thermos cup

- Electric heater

- Cooking pots and pans

- Electronic scale

- Coffee machine

- Automatic lawn mower

- Blender

- TV holder

Car accessories

- Car humidifier/air filter

- In-vehicle video camera

- Car mobile phone holder

Sport accessories

- Paddle

- Electric skateboard

- Massage accessory

Self-service machines

- Self-service card issuing machine

- Self-service payment machine

- Self-service printer

Other

- 3D printer

- Receipt printer

- Rolling advertisement light box

- Multimeter