The product life cycle

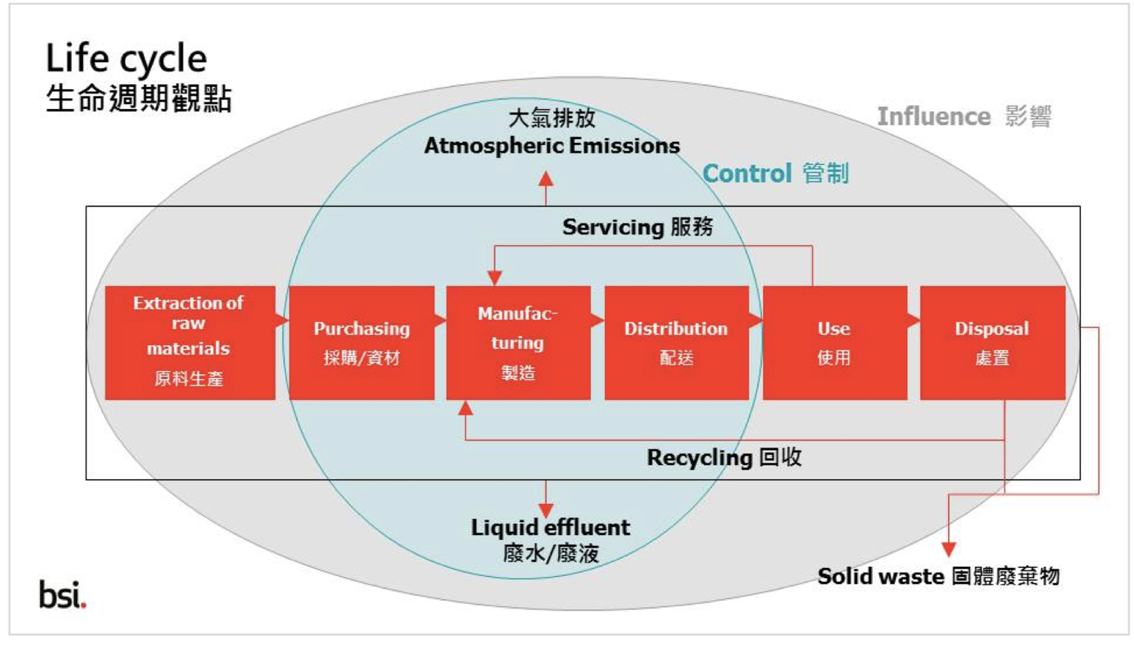

Here is a nice representation (by BSI) of the life cycle perspective:

The definition of Life cycle is:

“Consecutive and interlinked stages of a product (or service) system, from raw material acquisition or generation from natural resources to final disposal. The life cycle stages include acquisition of raw materials, design, production, transportation/ delivery, use, end-of-life treatment and final disposal.”

We hold BSI ISO 14001 which shows our commitment to reducing our environmental impact and that of the products we develop and manufacture:

How our different teams reduce our impact on the environment

R&D Team

- Reduce the product’s normal usage consumption of electricity or water (or other utilities/consumables).

- Make it more reliable & durable, so that its useful life is extended.

- Suggest more environmentally friendly materials.

- Make the product easier to repair, easier to dismantle and recycle, etc.

- Make it safe and compliant.

Sourcing/Buying Dept.

- Suggesting greener suppliers to our customers, and we pick some of the criteria when sourcing

- Deciding on the criteria when auditing suppliers

- Staying on top of the schedule, so late deliveries are less likely (reducing the likelihood of air freight, or cutting a shipment into 2 shipments)

- We may decide to switch to another supplier, and again we set the selection criteria.

- We try and re-use materials that are already in stock rather than buy new ones (when it does not have adverse effects on quality/reliability).

Quality team

When we manage product quality, we have control over many aspects that can help us be more eco-friendly:

- We work with suppliers to clarify the standard, make sure their process controls are adequate, etc, driving them to reduce problems and defects so there’s less scrap.

- We do the same internally, and altogether it leads to reduced scrap, reduced re-processing, and reduced issues after delivery.

- We follow a systematic NPI process, we validate the important elements in order to reduce risks. We do pilot runs before going into mass production. We fix the major issues, so they don’t appear on many pieces.

Production Dept.

When managing production, we control the following, which can make a big difference:

- We plan carefully, so the likelihood of delays (which can lead to air freight, etc.) is lower.

- We prepare work instructions for workers, train them, etc. in order to minimize scrap and rework.

- We work efficiently so we don’t need excessive people and space to meet your objectives.

- We feed information back to quality, purchasing, etc. so any issues are fixed at the root (again reducing waste).

- We recycle as many unused materials as possible.

Warehousing and Logistics

- We are organized so we don't lose materials in the warehouse.

- We keep on top of ageing materials and try and minimize obsolescence which causes waste.

- We try not to use excessive space and people to do the job.

We’re here to help, so if you have any questions about manufacturing your product, get in touch and we’ll try to give you some helpful advice and confirm if we’re able to help you: