We’ve already covered the first startup killer: “The Market,” and how to plan for a proper ‘customer development’ process in a hardware startup. In this article, we’re going to focus on the second killer, “Technical Mistakes,” and the challenges in designing, developing, and manufacturing a product that meets requirements and can be produced at scale.

Table of Contents

ToggleLet’s start by looking at a few examples of high-profile products that did not make it to market because of technical issues. Then, let’s cover some of the ‘good practices’ the best teams follow.

Technical problems are a common product-killer

The internet is littered with failed products that made a splash, gained worldwide adulation in some cases, and then sank without a trace when it was time to mass-produce them, leaving backers out of pocket and fans in confusion.

“The Coolest Cooler” holds the dubious honor of being the most famous Kickstarter failure:

(Image credit: Kickstarter)

They raised around US$13,000,000 for a cooler… pretty amazing for this kind of product. One would assume that they could get this to market, but it failed as they didn’t focus on DFM (Design for Manufacturing) and had unwittingly created a product that could be prototyped, but not industrialized.

Here is what we wrote about this failure:

[The product] was wildly popular, but it wasn’t possible to get it into production with the advertised features at the planned price.

The cooler itself included tons of great features, such as an ice maker, waterproof Bluetooth speaker, LED light, USB charger, and more. Sounds perfect, BUT the problem was that they couldn’t go from prototype to mass-produced model. Manufacturing strikes and US tariffs on Chinese products were also cited as reasons the startup failed. However, this isn’t the first product where they made an awesome prototype, but didn’t engineer it to be manufacturable at scale.

The startup should have been ready for manufacturing before launching their crowdfunding campaign. They had not completed the ‘discovery’ phases of the NPI process and were not in the required ‘delivery mode.’

Some other high-profile crowdfunding failures

There are others, as well. Read about these failures that struggled with technical difficulties and couldn’t be made here:

- Tiko 3D printer (US$2.9m raised)

- Zano Drone (US$3m raised)

These different Kickstarter failures all have one thing in common. They promised features, technologies, or a form factor that just weren’t technically possible to mass-produce.

How to avoid being the next product on the scrap heap

Here’s some advice on how to reduce the risk of running into technical issues when making your new product. Following a structured NPI process helps ensure that you are producing a product that can be manufactured with fewer risks:

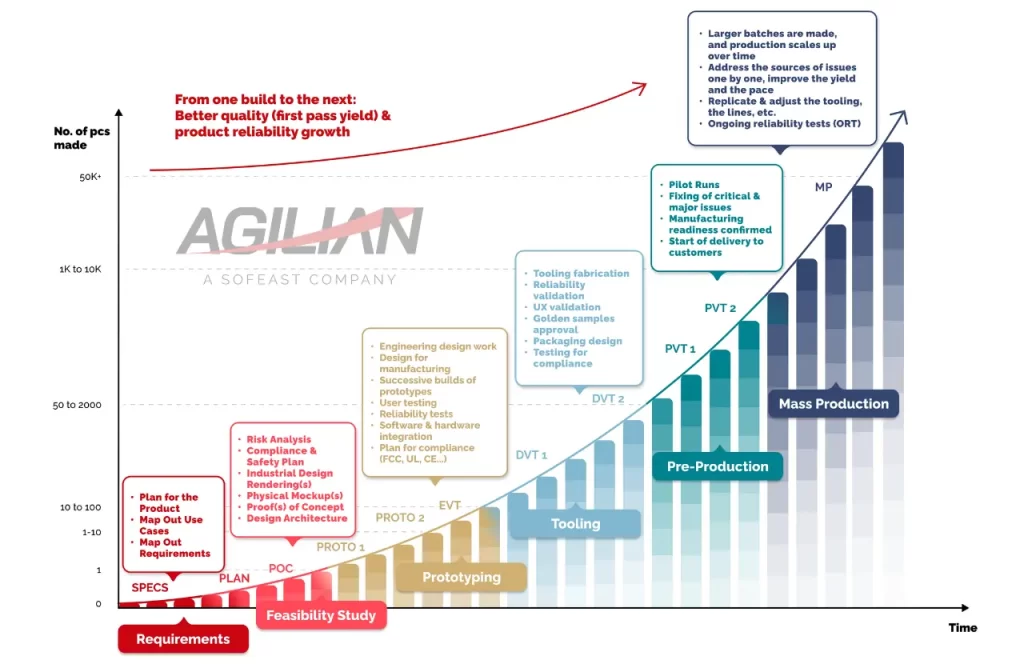

We’ll address key points from this graph in more detail here for you to take away.

1. Define Clear Product Requirements

Start by developing specific, verifiable requirements based on user needs:

- Avoid subjective specifications like “sound must be very good” or “must feel light”

- Use measurable criteria: “audio distortion should be less than 10% at 90 dB SPL” or “weight should not exceed 30 grams”

- Work with development engineers to define appropriate validation criteria

When manufacturing in Asia, clear requirements help bridge communication gaps and ensure your manufacturing partner delivers what you need rather than what they think you want.

2. Evaluate Technology Readiness Level (TRL) of critical components

The technologies you incorporate directly impact your risk profile:

- Assess the Technology Readiness Level of each critical component

- Prioritize proven technologies with established manufacturing processes

- When innovation is necessary, isolate high-risk elements for focused development

Using technologies your manufacturing partner has experience with significantly reduces production challenges and quality issues.

For instance, in early 2025, there is talk of “axial flux” electric motors, which provide extra efficiency, yet they are still far from mainstream. If you pick this technology for your product, you are betting that it will develop pretty fast into a reliable and mass-manufacturable component. It is an opportunity but also a big risk.

3. Simplify Your First Version

A common mistake is overcomplicating the initial product release:

- Focus on core functionality that delivers genuine user value

- Eliminate nice-to-have features that add complexity

- Reduce custom components where possible

Each additional feature exponentially increases development complexity, time, and cost.

Here are useful resources on this topic:

- We wrote about What Makes a Great Version 1.0 Product before and about what Jason Cohen calls a “simple, lovable, and complete” product. Make sure to think about this before you finalize a list of features for your product.

- If the product unit cost is too high relative to what the market will accept, think of ways to reduce that cost. Caleb Vainikka came up with a nice list in this Linkedin post, to get your thinking going.

4. Address Team and Execution Risk

Most hardware startups need 0.5 to 2 million USD in funding, so founders usually need to raise capital. This is why you need to learn about the way professional investors such as venture capitalists (VCs) think.

Here is what famous VC Andreesen wrote about “The Onion Theory of Risk”:

You can think of a day 1 startup as having every conceivable kind of risk: founding team risk, product risk, technical risk, market acceptance risk, revenue risk, cost of sales risk, viral growth risk, etc.

A startup is basically just a long list of risks, and as Andreesen explains:

“The way I think about running a startup is the way I think about raising money. It’s a process of peeling away layers of risk as you go.”You raise seed money to peel away the first two or three risks (e.g. founding team risk, product risk, initial launch risk).

You raise the Series A round to peel away the next layer of risks (e.g. recruiting risk, customer risk, revenue risk, cost of sales risk)

And so on.

Basically, you’re peeling away risk as you’re achieving milestones. And as you achieve milestones, you’re both: making progress on your business and justifying raising more capital.

As Andreessen emphasized, people/team problems often sink startups.

Advice for hiring the right team

- Prioritize team members with hardware development experience

- Ensure key personnel have experience managing overseas manufacturing relationships, if needed

- Ensure your project manager understands how the NPI process works

- Consider bringing in contractors and/or consultants with specific expertise your team needs, and consider working with a contract manufacturer that has R&D capabilities if that make sense

The management of the product development project is sometimes done very well, and sometimes it is done very poorly. When a lot of moving elements are involved, it is often called “program management” to reflect the level of complexity involved.

If you tackle a new product development for the first time and if the product design is not simple, you will probably be in over your head within a few months. A program manager with prior experience in (generally) the same product category can save your company from falling into dozens of pitfalls. It translates into shorter time to market and burning much less cash.

Execution discipline

- Implement clear decision-making processes, and make sure to appoint a “tech lead” who will manage the various engineers & designers working on product development.

- Establish regular communication cadences and some synchronization milestones to integrate the feedback from the market (see our article on market risk)

- Create accountability mechanisms for both internal teams and external partners

- Develop contingency plans for inevitable industrialization & production challenges

5. Follow a Proven Product Development Process

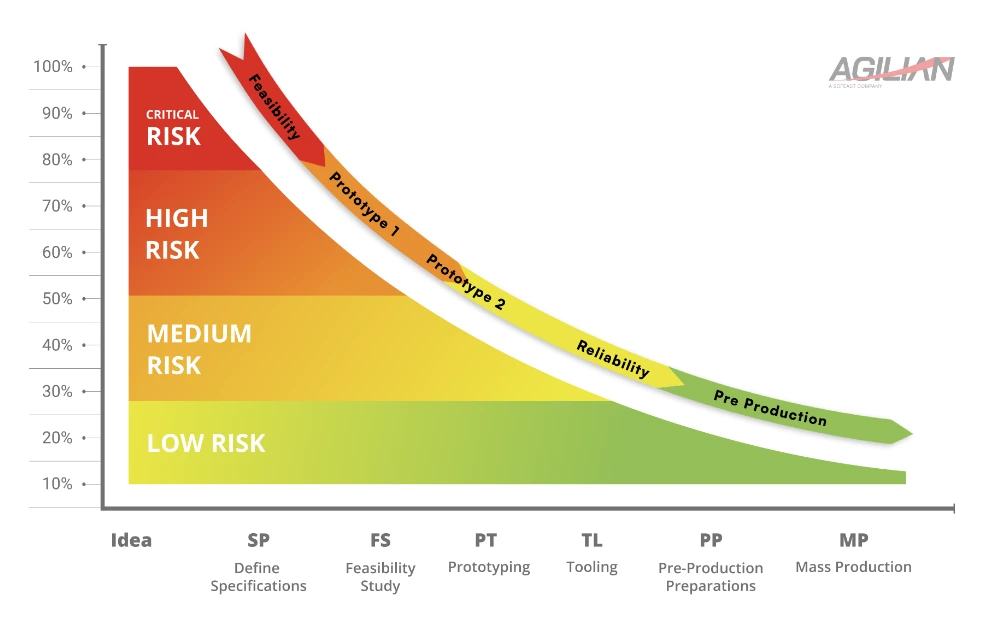

Reduce risk through methodical development:

- Begin with proof-of-concept/feasibility studies to validate key assumptions

- Conduct early testing of critical components if they present a performance or reliability risk

- Select suitable suppliers with consistent quality performance

- Implement design best practices for manufacturing, testing, and reliability

- Execute iterations of plan-design-prototype-test, and do not forget to (pre)test for reliability and compliance

As you can see in this simplified graph, risks reduce as you progress through the product development stages towards mass production:

6. Key Validation Steps in Product Design & Development

After some initial design work has been done and development progresses, there are now some key Validation Steps (or milestones).

- Functional prototypes achieving core requirements with positive user feedback

- Compliance pre-testing passed

- Reliability validation through accelerated life testing

- Final prototypes verified against all product requirements

- Design for Manufacturing (DFM) review for confirmation

- Product design can be frozen

7. Manufacturing Transfer

When transitioning to production, here are good practices for reducing risk:

- Engage a suitable contract manufacturer with relevant experience and get them involved in DFM early

- Ideally, conduct a process FMEA (Failure Mode and Effects Analysis) exercise that involves the contract manufacturer

- Develop comprehensive manufacturing quality plans

- Evaluate tooling samples for aesthetic and functional issues

- Plan sufficient pre-production pilot runs (often called ‘PVT’) before high-volume production

8. End of Manufacturing Transfer: The Readiness Assessment

Do not let an over-enthusiastic manufacturer convince you that everything is ready. They make money on mass production, but you will need to deal with unhappy customers and their returns.

Before scaling production volumes up, you need to evaluate:

- First pass yield rates

- Manufacturing process stability

- Testing effectiveness and efficiency

- Outstanding engineering changes requiring resolution

9. Overall, what does the NPI process look like?

In electronics, most companies use the phrase “New Product Introduction” (NPI). It covers all the steps from the initial product concept definition until mass production.

Here is how we have summarized it in a graphical form:

You can watch a video about how we follow this process on this page. We cannot over-emphasize how important it is for your startup to follow a proven NPI process.

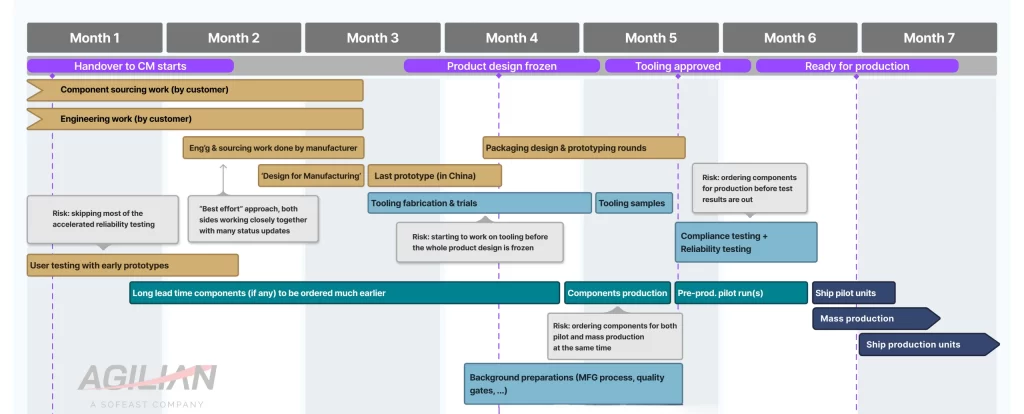

Do you need to go faster?

Many companies work with their contract manufacturer to find ways to compress the timelines between the product design freeze and mass production launch. Here is what it often ends up looking like:

As you can see, many of these time compression decisions come with extra risk of running issues… which means the likelihood of having to spend more money and more time goes up a lot. In other words, it is doable if it’s well planned & well executed by a well-experienced contract manufacturer, and you are lucky.

Ways to start delivering small quantities to market earlier

If you feel the need to start delivering finished products in the hundreds before investing in the development of the manufacturing process (including metal tooling fabrication etc.), you may need to use prototyping methods such as 3D printed molds.

We wrote about this in Do A Bridge Production Rather Than Rushing Into Mass Production. The unit cost is typically higher, but you get the product much earlier, and it can be a great way to get further feedback from the market. You still have a certain degree of design freedom at this point.

A variant of this may involve building a “version 0.9” that does the job, is not as well finished as production tooling would allow, but can be assembled in small quantities by your team internally. We wrote about the pros & cons of this approach in Starting Domestic Assembly then Moving Manufacturing to China (Pros & Cons).

Conclusion

There are proven ways to systematically plan ways to reduce the risk of running into technical issues at each stage on the way to high-quantity production. Ignore them, and your chances of survival will be much slimmer.

While this approach requires more upfront planning and more careful execution, it dramatically reduces costly delays and quality issues that plague many hardware startups.

About Renaud Anjoran

Renaud is a recognised expert in quality, reliability, and supply chain issues and is Agilian's Executive VP. He has decades of experience in electronics, textiles, plastic injection, die casting, eyewear, furniture, oil & gas, and paint. He is also an ASQ-Certified ‘Quality Engineer’, ‘Reliability Engineer’, and ‘Quality Manager’, and a certified ISO 9001, 13485, and 14001 Lead Auditor.